Cowgirl Rustic Posies Cuff Bracelet, Pendant, and Earrings

- Metal Maven

- May 10, 2020

- 9 min read

Updated: Jul 18, 2022

Using the Cowgirl Rustic Cuff Bracelet Pressing you can make your own Cuff Bracelet, Pendant, and Earrings. Here's a quick tutorial to walk you through the steps!

This pressing is called “Cowgirl Rustic“ because it has design elements that mimic hand tooled leather designs commonly found on western saddlery and other items like western belts and boots.

The pressing provides you with two bracelets that are approximately 1-1/4" wide. For this project, Metal Maven used a guillotine shear to cut the pressing into two pieces.

Metal Maven used one side of the pressing to make a bracelet and then used the other half to fashion a pendant and a set of earrings.

To create your own bracelet, pendant, and earrings, you will need Metal Maven's Cowgirl Rustic Posies Cuff Bracelet pressing in Copper or Sterling Silver.

CUTTING THE CUFF BRACELET

Metal Maven Tip: Use a fine tip Sharpie to trace around the outside of the cuff edge. This makes it much easier to see when cutting each piece out.

Place your marked pressing on your Guillotine Shear and cut on the line you marked along the edge of the cuff strip. If you don't have a Guillotine Shear, use a jeweler's saw to saw along the line.

Metal Maven Tip: I use a Saw Blade Size of #2/0 when sawing 20-gauge metal, a #1/0 saw blade when sawing 18-gauge metal and a #1 saw blade when sawing 16-gauge metal. Check out this saw blade specification chart on Rio Grande's website for recommended Saw Blade Sizes.

FILING AND SANDING

The cuff strip is now ready for the next steps. In order to make the cuff comfortable to wear, you need to round the sharp corners and smooth the edges with a file.

Metal Maven used a small belt sander from Micro Mark to sand the edges and round the corners. If you do not have a belt sander, use a #5 file to smooth the edges and round the corners.

Next, Metal Maven used a JOOLTOOL to further smooth the edges and the corners of the cuff strip. Use a Very Fine 3M Scratch Eraser on the JOOLTOOL to burnish the edges.

If you don't have access to a JOOLTOOL, use 800 grit wet/dry sandpaper to smooth the edges of the entire cuff strip edges and the rounded corners.

Metal Maven Tip: An easy way to sand the sides and ends is to lay a piece of sandpaper on a clean flat surface, hold the cuff strip on it's edge and slide it back and forth. Tilt the cuff strip at an angle to round and smooth the edges.

Next, further smooth the edges of the long sides and ends again with 1000 grit wet/dry sandpaper.

ADDING A PATINA

This step is optional.

Adding a patina brings out the details of your piece and adds an antique-looking quality.

Oxidize with Liver of Sulfur or your choice of blackening agent.

Next, use 2000 grit extra fine wet/dry sandpaper to very lightly sand the oxidation from the raised areas on the bracelet. Wet/dry sandpaper can be purchased at most home improvement stores.

FORMING THE CUFF BRACELET

You will need to use a Oval Bracelet Forming Mandrel and a nylon hammer, a urethane hammer, or a rawhide mallet to form the bracelet. Line up the middle of the bracelet strip on top of the mandrel and push the edges down to form a U-shape. Next, hold the two ends from underneath so that the bracelet doesn't shift, and use your hammer or mallet to continue forming the bracelet around the mandrel by tapping lightly.

Metal Maven Tip: I prefer a Stepped Oval Bracelet Mandrel because each step on the mandrel has graduated sizes and a level surface instead of of being cone shaped.

If you don't have a bracelet mandrel, I can recommend the Cast-Iron Stepped Oval Bracelet Mandrel with Tang from Rio Grande. This is the one that I use. (Rio has not paid me or compensated me in any way for recommending their products.)

You can find the Mandrel here:

Metal Maven Tip: To protect the inside surface of the bracelet, cover your mandrel with a piece of soft leather so that as you hammer, marks from your mandrel will not transfer onto the inside of your bracelet.

Metal Maven Tip: You can also use Joni Kisro's Bracelet Bender for ring, bracelet, and bangle forming. I own one of these and I highly recommend it, it's a fantastic tool. Joni has given me permission to share her Youtube video showing how to use the Bracelet Bender.

Joni’s Bracelet Bender available from Daniel Urrea website.

FINAL POLISHING WITH A ROTARY TUMBLER

Your bracelet is now ready to polish with a rotary tumbler. If you don't have a tumbler you can hand polish with a Sunshine Polishing Cloth.

When using a rotary tumbler, fill the tumbler barrel half full with stainless steel shot, add tap water just to the top of the steel shot, add a drop or two of Dawn, then tumble for at least 2 hours.

FINISHED PRODUCT

MAKE THE MATCHING EARRINGS WITH THIS PRESSING:

First you will need to plot where you want your earring cutouts on your pressing. You can freehand your designs or make a template, or you can use a round disc cutter.

TIP: An easy way to make a reusable see-through template is to find something plastic that you no longer need like a lid to plastic food container! Cut the middle out of the lid with an X-ACTO knife. Then draw your circle on the plastic with a fine tip Sharpie. Cut out the circle using your X-ACTO knife. Now you have a see-thru template that you can move around your pressing to plot out where you want your earring design.

Mark the metal using a Sharpie with your template. Saw out the marked shape.

Metal Maven Tip: I use a Saw Blade Size of #2/0 when sawing 20-gauge metal, a #1/0 saw blade when sawing 18-gauge metal and a #1 saw blade when sawing 16-gauge metal. Check out this saw blade specification chart on Rio Grande's website for recommended Saw Blade Sizes.

FILING AND SANDING

The earring is now ready for the next steps. In order to make the earring comfortable to wear, you need to round the sharp corners and smooth the edges with a file.

Metal Maven used a small belt sander from Micro Mart to sand the edges and round the corners. If you do not have a belt sander, use a #5 file to smooth the edges and round the corners.

Next, Metal Maven used a JOOLTOOL to further smooth the edges and the corners of the earring. Use a Very Fine 3M Scratch Eraser on the JOOLTOOL to burnish the edges.

If you don't have access to a JOOLTOOL, use 800 grit wet/dry sandpaper to smooth the edges of the earring and the rounded corners.

Metal Maven Tip: An easy way to sand the sides and ends is to lay a piece of sandpaper on a clean flat surface, hold the earring on it's edge and slide it back and forth. Tilt the earring at an angle to round and smooth the edges.

Next, further smooth the edges of the long sides and ends again with 1000 grit wet/dry sandpaper.

ADDING A PATINA

This step is optional.

Adding a patina brings out the details of your piece and adds an antique-looking quality.

Oxidize with Liver of Sulfur or your choice of blackening agent.

Next, use 2000 grit extra fine wet/dry sandpaper to very lightly sand the oxidation from the raised areas on the earring. Wet/dry sandpaper can be purchased at most home improvement stores.

DRILLING EARWIRE HOLES

Mark where you want your holes with a fine tip Sharpie. If you plan to use a drill bit in your flex shaft or drill press to drill your hole, use a sharp tipped awl or nail and a hammer to put a dimple in the center of your mark first. The dimple will help keep your drill bit from dancing all around on your piece when you drill your hole.

Drill your hole.

Some drill bits leave a rough edge around your hole. A round tipped bur or a setting bur works well to remove the rough edges on your holes. The burs can be used with a flex shaft or simply hold them with your fingers. Place the edge into the hole and twist gently in a clockwise motion until the rough edge is removed.

FINAL POLISHING WITH A ROTARY TUMBLER

Your earrings are now ready to polish with a rotary tumbler. If you don't have a tumbler you can hand polish with a Sunshine Polishing Cloth.

When using a rotary tumbler, fill the tumbler barrel half full with stainless steel shot, add tap water just to the top of the steel shot, add a drop or two of Dawn, then tumble for at least 2 hours.

MAKING COPPER EARWIRES

For the copper earrings, make some copper earwires using a handy little tool called the "Easy Ear Wires" tool. Open the earwire loop to the side and attach to the piece through the drilled hole. Close the open loop.

Tip: If you have Sterling Silver wire you can also make silver earwires using the same tool or purchase earwires from a jewelry making supplier like Rio Grande.

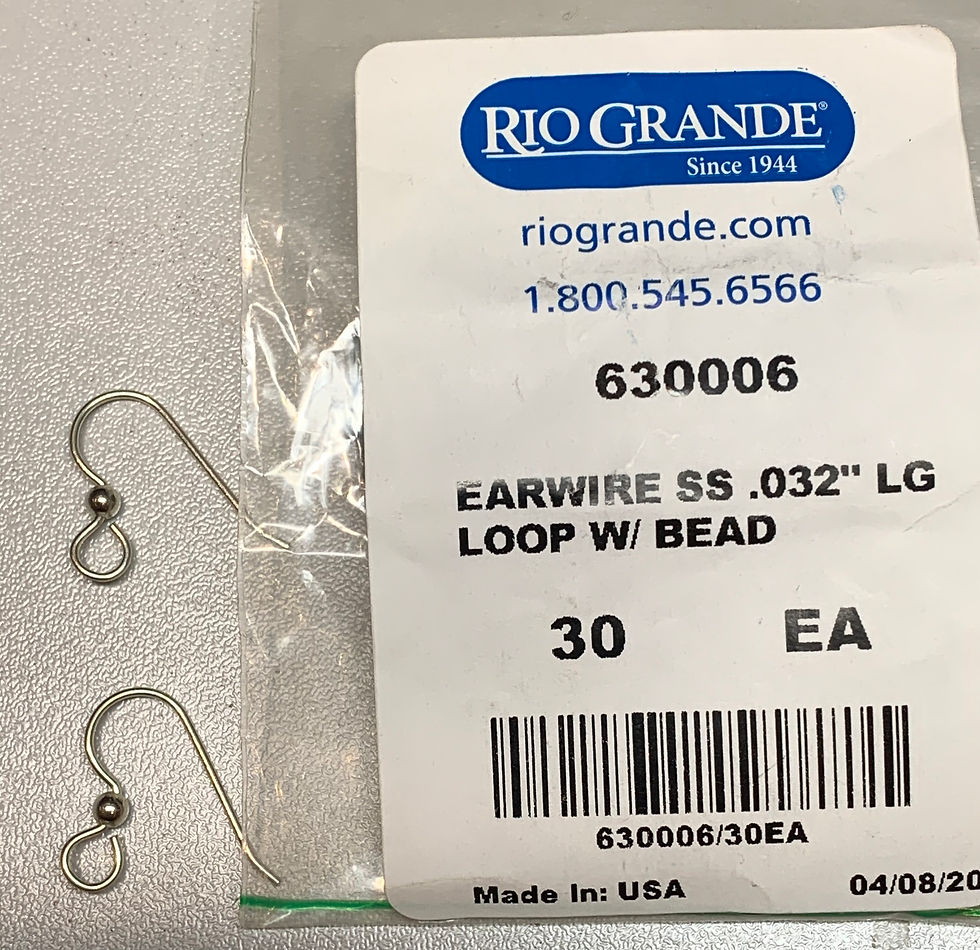

Adding the Sterling Silver Earwires

Metal Maven recommends using Sterling Silver earwires from Rio Grande. They are relatively inexpensive and allow you to market your earrings as being good quality as opposed to base metal earwires. Here are the earwires used for these earrings.

Opening the earwires.

A good technique for attaching the ear wire loop to your piece involves opening the loop to the side instead of pulling it out from the ball. Grab a pair of chain nose pliers and hold the open end of the loop. See the photo below.

Now hold the earwire with your fingers and bend the loop towards you or away from you. The loop will look like the photo below if you have done it correctly. Next, put the open loop through the hole at the top of your piece. Using the pliers again, bend the open loop back into place. Be sure to face the front of the earring to front side of the earwire.

FINISHED PRODUCT

MAKING THE PENDANT WITH THIS PRESSING:

First you will need to plot where you want your pendant cutout on your pressing. You can freehand your designs or make a template, or you can use a round disc cutter.

TIP: An easy way to make a reusable see-through template is to find something plastic that you no longer need like a lid to plastic food container! Cut the middle out of the lid with an X-ACTO knife. Then draw your circle on the plastic with a fine tip Sharpie. Cut out the circle using your X-ACTO knife. Now you have a see-thru template that you can move around your pressing to plot out where you want your pendant design.

Mark the metal using a Sharpie with your template. Saw out the marked shape.

Metal Maven Tip: I use a Saw Blade Size of #2/0 when sawing 20-gauge metal, a #1/0 saw blade when sawing 18-gauge metal and a #1 saw blade when sawing 16-gauge metal. Check out this saw blade specification chart on Rio Grande's website for recommended Saw Blade Sizes.

FILING AND SANDING

The pendant is now ready for the next steps. In order to make the pendant comfortable to wear, you need to round the sharp corners and smooth the edges with a file.

Metal Maven used a small belt sander from Micro Mart to sand the edges and round the corners. If you do not have a belt sander, use a #5 file to smooth the edges and round the corners.

Next, Metal Maven used a JOOLTOOL to further smooth the edges and the corners of the pendant. Use a Very Fine 3M Scratch Eraser on the JOOLTOOL to burnish the edges.

If you don't have access to a JOOLTOOL, use 800 grit wet/dry sandpaper to smooth the edges of the pendant and the rounded corners.

Metal Maven Tip: An easy way to sand the sides and ends is to lay a piece of sandpaper on a clean flat surface, hold the pendant on it's edge and slide it back and forth. Tilt the pendant at an angle to round and smooth the edges.

Next, further smooth the edges of the long sides and ends again with 1000 grit wet/dry sandpaper.

ADDING A PATINA

This step is optional.

Adding a patina brings out the details of your piece and adds an antique-looking quality.

Oxidize with Liver of Sulfur or your choice of blackening agent.

Next, use 2000 grit extra fine wet/dry sandpaper to very lightly sand the oxidation from the raised areas on the pendant. Wet/dry sandpaper can be purchased at most home improvement stores.

DRILLING JUMP RING HOLES

Mark where you want your holes with a fine tip Sharpie. If you plan to use a drill bit in your flex shaft or drill press to drill your hole, use a sharp tipped awl or nail and a hammer to put a dimple in the center of your mark first. The dimple will help keep your drill bit from dancing all around on your piece when you drill your hole.

Drill your hole.

Some drill bits leave a rough edge around your hole. A round tipped bur or a setting bur works well to remove the rough edges on your holes. The burs can be used with a flex shaft or simply hold them with your fingers. Place the edge into the hole and twist gently in a clockwise motion until the rough edge is removed.

ATTACH JUMP RING AND CHAIN

Add a jump ring that is large enough to pass the end of your chain through.

Metal Maven Tip: It's a best practice to solder or weld your jump ring.

FINAL POLISHING WITH A ROTARY TUMBLER

Your pendant is now ready to polish with a rotary tumbler. If you don't have a tumbler you can hand polish with a Sunshine Polishing Cloth.

When using a rotary tumbler, fill the tumbler barrel half full with stainless steel shot, add tap water just to the top of the steel shot, add a drop or two of Dawn, then tumble for at least 2 hours.

FINISHED PRODUCT

Comments